Polymer Composite Materials for Efficient Separations and Energy Applications

Research Materials

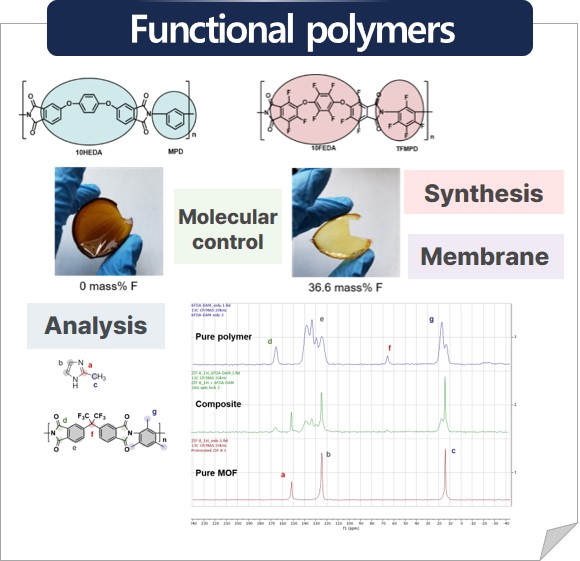

1. Polymers

Polymers have been in past decades systematically synthesized to demonstrate structure-property relationships. Our group focuses on a variety of functional polymers below:

- Glassy polymers: Polyimides & microporous polymers for diffusion-based transport

- Rubbery polymers: Poly(ethylene glycol)s and ionic liquids for solubility-based transport

- Phase-separated copolymers: Block & graft copolymers for high application performance and physical property.

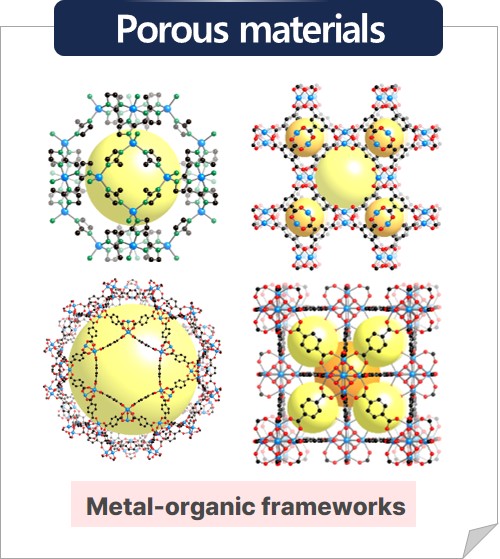

2. Porous Materials

Metal-organic frameworks are composed of metal ions or metal clusters coordinatively bridged by organic ligands. Our lab has been rationally designing new metal-organic frameworks to obtain significantly enhanced thermodynamic and kinetic molecular separation.

- Kinetic separations: ZIF-8, ZIF-67, UiO-66, MIL-53.

- Thermodynamic separations: HKUST-1, MOF-74, MIL-100, MIL-101.

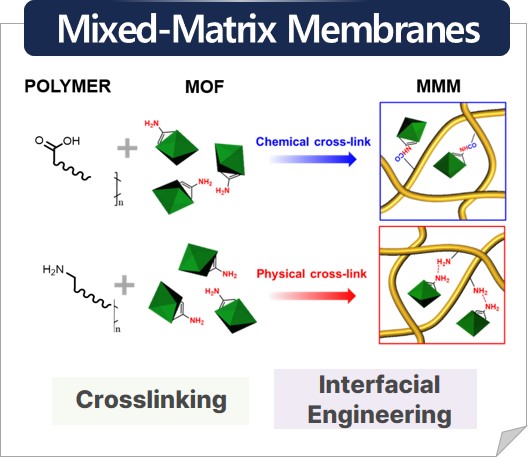

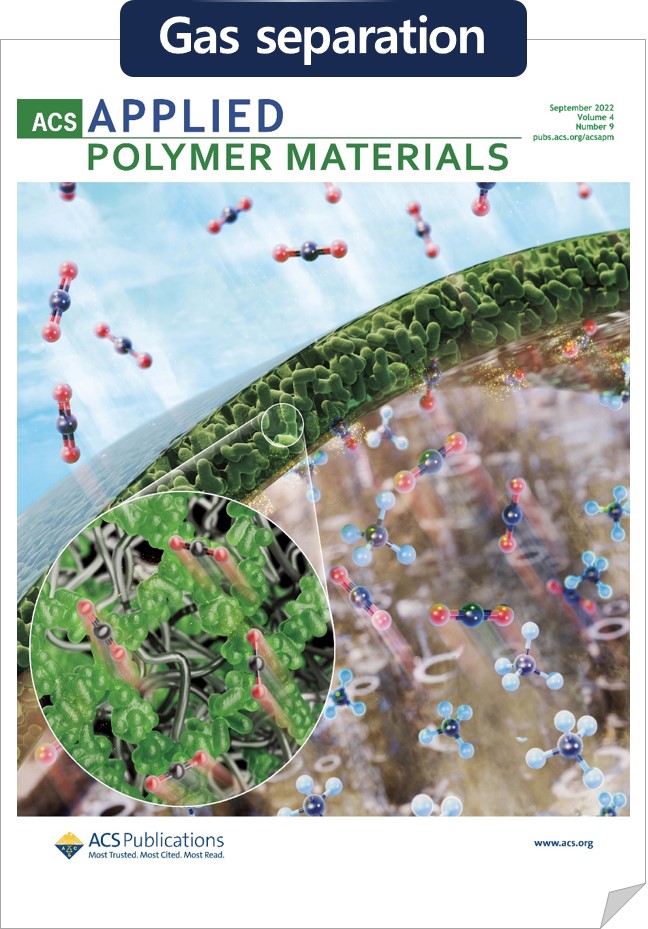

3. Mixed-Matrix Membranes

Mixed-matrix membranes are composed of inorganic materials and polymer matrix as a composite to form hybrid material. The mixed-matrix membranes harness the processability of polymers while simultaneously overcoming the upper bound trade-off between permeability and selectivity due to the porous nature of inorganic materials.

- Good mechanical stability and processability

- Controllable separation parameters (porosity, molecular sieving effects, and sorption ability)

- Interfacial engineering between inorganic materials and polymer matrices can be designed to optimize molecular diffusion and selectivity.

Target Applications

1. Separations

The separations industry consumes 15 quadrillions BTU of energy per year, which is approximately 50% of the total energy consumed by the industrial sector as a whole. Thermally driven separations, such as distillation, rely on liquid-vapor phase changes to accomplish separation. It is estimated that replacing distillation, for this separation among other large scale applications, with more energy-efficient methods could save up to 90% in energy costs, eliminating 100 million tons of CO2 emissions and saving $4 billion in energy costs per year. Our lab will focus on energy-efficient membrane-based separations to meet energy and environmental concerns.

- Hydrogen separations: H2 recovery from hydrocarbons, H2 purification from reforming, H2 removal from NH3 purge, and syngas ratio adjustment.

- Carbon dioxide capture and removal: CO2/CH4/H2S separation for natural gas sweetening, CO2/N2 separation for flue gas from power and industrial exhaust gases, CO2/H2 separation for syngas, coal, or gas-to-chemical applications.

- Olefin/paraffin separations: ethylene/ethane separations, propylene/propane separations for high-grade chemicals and products.

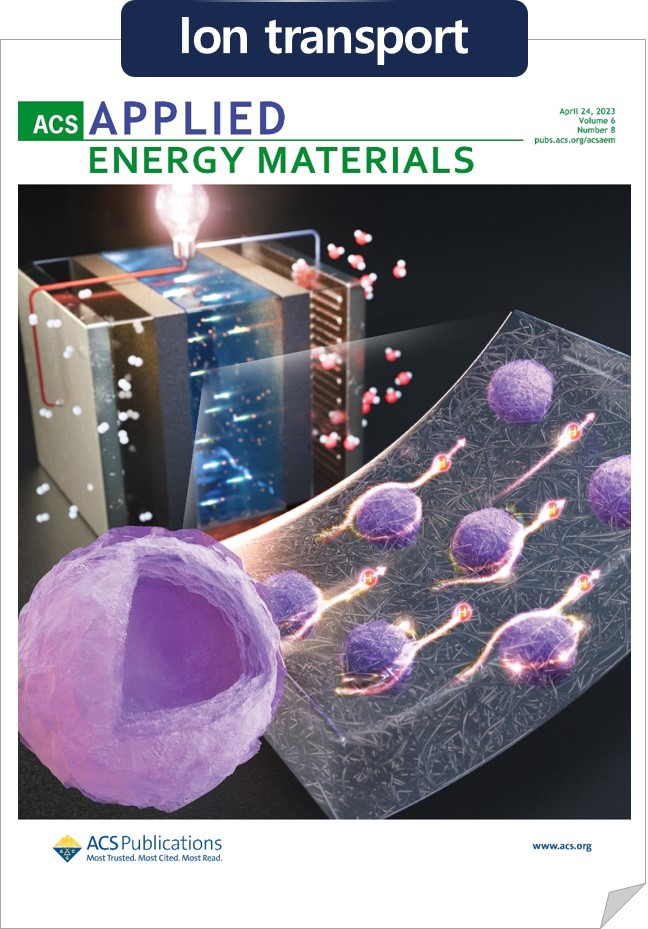

2. Electrochemistry

Harnessing renewable energy is one of the most effective strategies to address current energy deficiency and environmental issues. It is required to develop new energy materials to achieve high energy efficiency and industrially applicable property sets. Polymer and porous materials are of great interest in next-generation electrochemical applications. In particular, our group focuses on hybrid materials composed of polymers and porous materials in the form of membranes. The membrane component in energy applications can assist in significantly improving electron transport to enhance energy efficiency as well as ion separation to maintain energy device stability.

- Fuel cells, water electrolysis: Proton exchange membranes, anion exchange membranes

- Batteries: Separators, electrolytes

3. Catalysts

Porous materials are promising candidates for catalyst application in the chemical industry such as methanol production and biodiesel production through the oxidation process. In particular, the metal-organic frameworks have crystalline structures with high surface areas favorable for catalyst reactions but low catalyst activity. Our group focuses on creating heterogeneous catalysts using metal-organic frameworks through the unit (either metal sites or organic ligands) functionalization in the framework. Additionally, the metal-organic frameworks with coordinatively unsaturated metal sites can Lewis acidic catalysts. In our lab, designing multi-functional catalysts exhibiting high catalyst performance and stability will be focused on.

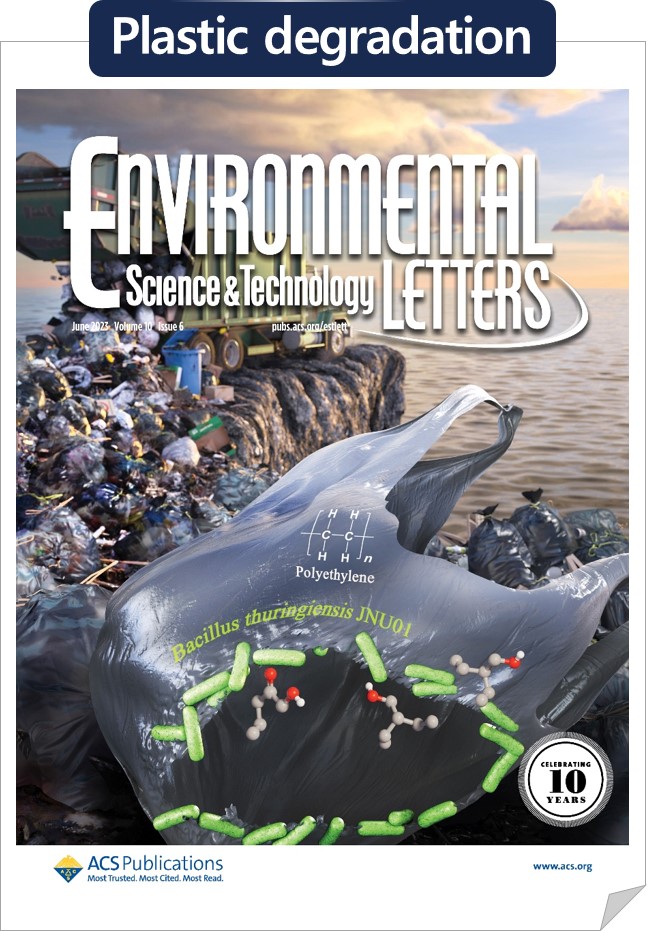

- Enzyme(bio) and inorganic(chem) materials: plastic degradation